Strategic Laboratory Selection for Junior Exploration Companies

Managing Assay Logistics in a Constrained Market

The Western Australian exploration sector continues to experience unprecedented activity, with junior companies driving much of the regional soil geochemistry and early-stage drilling programs. However, this growth has exposed critical bottlenecks in analytical capacity that directly impact project timelines and capital efficiency.

For junior explorers, analytical laboratory selection represents a strategic decision that influences everything from drill targeting precision to investor communication schedules. Understanding how to navigate current market constraints while maintaining analytical quality is essential for competitive advantage.

Understanding Current Market Dynamics

Capacity Constraints and Prioritization Systems

Most established laboratories operate on tiered service models where sample throughput and turnaround times correlate directly with contract value and client relationships. This creates predictable delays for smaller sample batches, particularly during peak exploration seasons when major producers and mid-tier companies consume primary capacity.

Current market data suggests routine soil geochemistry packages (typically 50-500 samples) face turnaround times of 3-8 weeks at major facilities, with potential extensions during Q1 and Q3 seasonal peaks. These delays compound when considering the iterative nature of exploration programs where results inform subsequent sampling campaigns.

Geographic and Logistical Considerations

Several junior companies have successfully utilised interstate or international laboratories to circumvent local capacity constraints. While shipping costs and logistics complexity increase, the time savings often justify the additional expense, particularly for time-sensitive programs or investor commitments.

Key factors to evaluate include:

- Sample preservation requirements during extended transport

- Customs and regulatory compliance for international shipments

- Chain of custody protocols across jurisdictions

- Communication challenges across time zones

Framework for Laboratory Selection

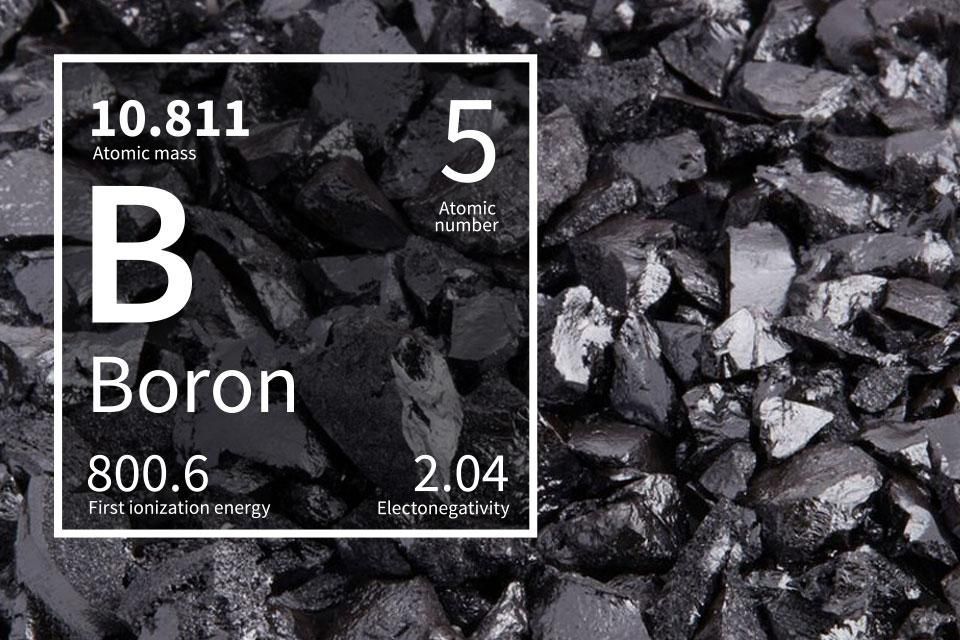

Analytical Requirements Assessment

Before evaluating laboratory options, establish clear analytical requirements:

Matrix Types and Sample Volumes:

- Soil geochemistry: typical detection limits and element suites required

- Rock chip assays: specific elements of interest and expected grade ranges

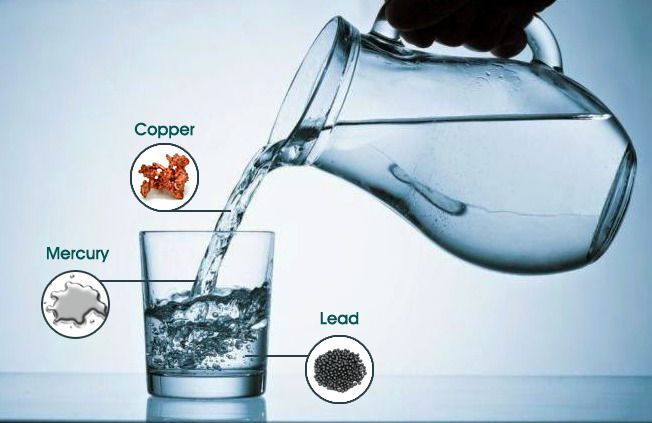

- Water analysis: regulatory compliance requirements vs. exploration screening

- Tissue analysis: if vegetation geochemistry is planned

Quality Assurance Protocols:

- Required precision and accuracy specifications

- Standard reference materials appropriate for your geological setting

- Duplicate analysis frequency and acceptance criteria

- Contamination monitoring requirements

Risk Assessment Framework

Schedule Risk:

- Impact of potential delays on critical path activities

- Availability of backup laboratory relationships

- Seasonal capacity planning considerations

Quality Risk:

- Laboratory accreditation and certification status

- Internal QA/QC procedures and transparency

- Historical performance data and client references

Financial Risk:

- Cost escalation potential during peak periods

- Payment terms and cash flow impact

- Hidden charges for sample preparation or additional analyses

Strategic Options for Junior Explorers

Option 1: Establish Multiple Laboratory Relationships

Maintain qualified vendor relationships with 2-3 laboratories across different geographic regions. This approach provides:

- Leverage for turnaround negotiations

- Backup capacity during peak periods

- Comparative quality assessment opportunities

- Geographic risk mitigation

Implementation:

- Conduct small-scale qualification trials with multiple labs

- Establish framework agreements with preferred pricing

- Develop standard operating procedures for laboratory rotation

Option 2: Integrated Field-Laboratory Workflow

Combine portable analytical techniques with traditional laboratory analysis to optimize sample selection and reduce total sample volumes:

Portable XRF Integration:

- Pre-screen samples to prioritise high-value targets

- Reduce routine samples requiring full ICP-MS/OES analysis

- Enable real-time decision making in the field

Staged Analytical Approach:

- Initial screening via rapid techniques

- Detailed analysis for anomalous samples only

- Quality control via traditional methods on subset

Option 3: Seasonal Capacity Planning

Align sampling campaigns with laboratory capacity cycles:

- Schedule routine programs during off-peak periods

- Reserve peak season capacity for time-critical samples

- Develop sample storage protocols for delayed submission

Emerging Laboratory Services

Specialized Exploration Laboratories

New entrants to the analytical market are targeting specific exploration workflows, offering:

- Optimised sample preparation for soil and regolith matrices

- Flexible batch processing for smaller sample volumes

- Transparent pricing without premium expedite fees

- Real-time sample tracking and progress reporting

Evaluation Criteria:

- Analytical method validation and accreditation status

- Quality control procedures and reference materials

- Client references from similar exploration programs

- Financial stability and business continuity planning

Technology-Enhanced Services

Modern laboratories are implementing automation and digital integration:

- Automated sample preparation systems reducing manual handling

- Digital chain of custody with real-time tracking

- Cloud-based data delivery and integration capabilities

- Mobile-optimised reporting for field access

Implementation Recommendations

Phase 1: Vendor Qualification (Months 1-2)

- Conduct comparative analysis using archived samples

- Evaluate communication protocols and reporting systems

- Assess quality control procedures and certifications

- Establish pricing frameworks for different sample types

Phase 2: Operational Integration (Months 3-6)

- Implement sample tracking and chain of custody procedures

- Establish quality control protocols including reference materials

- Develop standard operating procedures for laboratory rotation

- Train field personnel on sampling and shipping requirements

Phase 3: Performance Optimization (Months 6-12)

- Monitor turnaround times and quality metrics

- Optimise sample batching and scheduling procedures

- Refine analytical packages based on geological requirements

- Develop contingency procedures for capacity constraints

Key Decision Points

When evaluating laboratory options, consider:

- Primary Selection Criteria: Determine whether turnaround time, analytical quality, or cost optimisation is your primary driver

- Backup Strategy: Establish secondary laboratory relationships before capacity constraints impact your program

- Quality Standards: Define minimum acceptable analytical precision and accuracy requirements

- Communication Requirements: Assess the importance of real-time sample tracking and progress reporting

- Geographic Considerations: Evaluate the trade-offs between local convenience and alternative options

Conclusion

Effective laboratory selection requires balancing multiple competing factors within current market constraints. The most successful junior exploration companies treat analytical services as a strategic partnership rather than a transactional relationship.

Whether working with established laboratories, emerging specialised services like Lambda Laboratories, or international alternatives, the key is developing robust evaluation criteria and maintaining flexibility to adapt to changing market conditions.

By implementing systematic vendor qualification procedures and maintaining multiple laboratory relationships, junior explorers can minimise schedule risks while maintaining analytical quality standards essential for successful exploration programs.